Kverneland u-drill plus

The Kverneland u-drill plus – the combined grain and fertiliser model of the universal trailed seed drill combination

Høydepunkter

High speed operation (10 – 18km/h) Perfect seed & fertiliser placement Modular frame concept for flexible adjustment Fully ISOBUS compatible Easy handling and maintenanceBeskrivelse

The Kverneland u-drill plus complements the product group of the universal seed drill combination available in 3.0m, 4.0m rigid and 4.0m and 6.0m folding. The u-drill plus carries out seedbed preparation, levelling, reconsolidation, seeding, fertilising and pressing in one pass - featuring high efficiency, large performance and high hectare output as main characteristics. The “plus” stands for the extra feature of the grain and fertiliser version to apply either grain and fertiliser or, alternatively, two different sorts of seeds at the same time. This has been achieved by the divided hopper equipped with two metering devices.

In order to balance the shorter vegetation phase, the phosphoric fertiliser application supports the initial germination and development of the plants in the most efficient way. In trials of spring sown crops, yields have shown increases up to 25% compared to crops where the fertiliser has been applied by other methods.

In addition, in current farming processes flexibility and strong performance are requested since the application of two different seeds in one pass has become more and more popular. The second crop mainly developing after the harvesting of the main crop.

Depending on the working width, the hopper capacity is either 3000l (3m and 4m) and 4350l (6m). The hopper of the rigid u-drill is divided lengthwise and the two metering devices are accordingly positioned either side. The proportion is 40 : 60.

The u-drill plus is especially adapted to suit the need of precise fertiliser placement at the seed. These crops can show substantial yield increase when applying fertilser with a relatively high percentage of phosphate together with the seeds. In Scandinavian and Eastern European countries the fertiliser is usaually placed between the rows besides and below the seed, whereas in other countries e.g. Scotland the preferred method is to apply both seeds and fertilser in the same row. In trials of spring sown crops, yields have shown increasses up to 25% compared to crops where ther fertiliser has been applied by other methods.

The u-drill plus is able to deliver fertiliser application rates up to 400kg/ha and 15km/h. The pressurised hopper system of the 6m version ensures these rates are maintained even under the most difficult conditions.

Advantages

- High speed operation (10 – 18km/h)

- Perfect seed placement

- Modular frame concept for flexible adjustment to customers’ requirements

- Fully ISOBUS compatible

- Easy handling and maintenance

- Automatically controlled headland management

Egenskaper

Step 1: Level the soil

For the best possible preparation, the front tyre packer levels the soil, crushes large clods and thus paves the way for the optimum depth control of the following tools. The front tyre packer has a diameter of 800mm. When it is not needed, it can be lifted hydraulically, simply by pushing a button..

Step 2: Prepare the seedbed

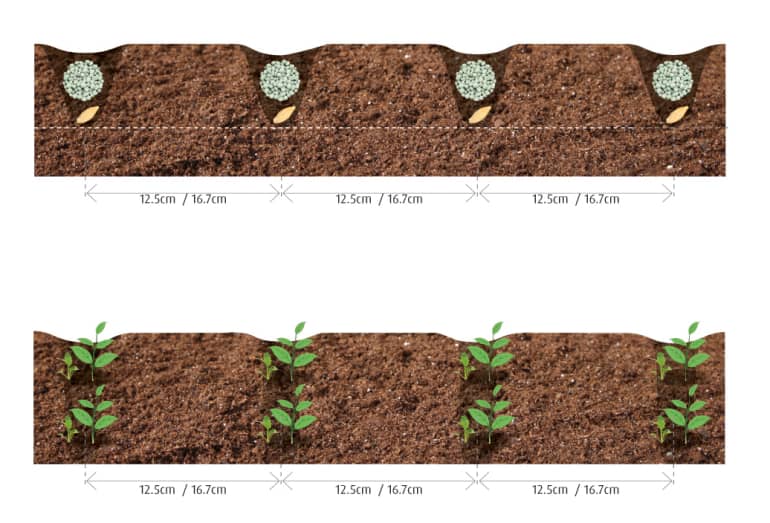

The disc harrow section consists of two rows of aggressively pitched conical discs. The discs are 5mm thick and hardened for long life. Thanks to their conical shape, the cutting angle remains constant. The high rotation speed ensures an excellent cutting quality over the entire working width. The distance between the sowing rows can be 12.5or 16.7cm.

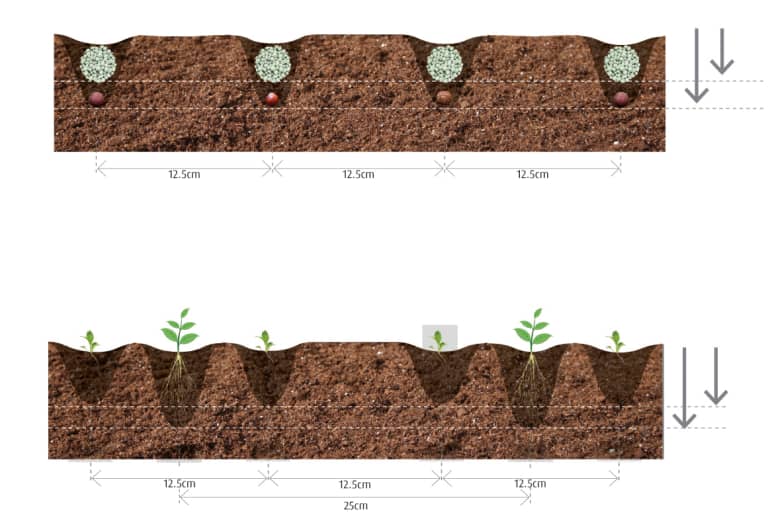

The MD disc section consists of two rows of straight waved discs. The MD disc have been designed for vertical penetration through the flutes. The blade keeps turning, penetrating and cutting even in the most challenging conditions. A seedbed is created only in stripes of 3 to 5 cm in width, in which the seed is placed by the CD coulter.

The MD disc section is available for machines with 16.7 cm row distance and with the u-drill plus in combination with double entry fertiliser injection.

Step 3: First pack, then seed

For perfect depth control of the coulters and an optimum seed-to-soil contact providing excellent capillary action, the loosened soil is re-compacted by a large tyre packer. The large tyre diameter of 900mm significantly reduces the tractive power required by the machine and thus ensures a consistently good work result.

Step 4: Drill and pack at constant seeding depth

The narrow profile of the coulters with their slightly offset steel discs allow easy penetration into the soil. Thus, little pressure is required at this point with only little soil being displaced. The coulter pressure of 100kg can, therefore, be primarily used for the pressing by the integrated press wheels. The result: a uniform seeding depth even at high working speeds! The seeding depth and the coulter pressure can be centrally controlled by the push of a button from the tractor cab – this saves additional time.

The stable depth control and the pressing of the seed produce a capillary system in the soil that ensures access to water and excellent germination

Step 5: Closing

Harrowing the soil completes the drilling. S-shaped or finger harrows ensure an optimum covering of the seeds. The working intensity can be set by the stepless pressure adjustment and at three different angles. To prevent damage to the harrow when reversing, it is equipped with an effective reversing device.

The u-drill comes with a fully automated headland management system. This saves the driver lots of time and eases the operation. Using just one button, the driver can initiate a headland sequence with wheels, discs and coulter bar all capable of automatic operation in timed stages. The lifting sequence starting with the disc section ensures a constant depth control until the headland.

As the headland sequence starts, the metering device stops automatically – avoiding double seeding. The seed hoses are empty at the headland. This saves up to 5% of seed.

The driver can concentrate on steering the machine and the correct operation. In addition double and/or missed seeding is prevented. With headland management the job can be done more quickly, precisely and efficiently. The drill requires only one double-acting spool to operate.

- ELDOS is electric driven by e-bas and e-com, the e-com edition is fully ISOBUS compatible, e-bas works as stand alone controlled system.

- GEOCONTROL by GPS signal is possible which avoids double seeding.

- Special sensors ensure functionality from the tractor cab.

- Five standard rotors are delivered: for fine and large seeds or fertiliser.

- The exchange of the rotors is quickly and easily done without any tools.

- Application rates from 1 to 400kg/ha are possible (depending on working speed and width).

- The metering device is always easily accessible.

Calibration

- Very simple calibration test due to the separate seed guidance.

- A remote control allows the driver to operate the calibration process at the metering device.

- No gear has to be adjusted. The driver simply enters the desired values into the terminal, presses one button to start at the metering device and that’s it.

- The calibration is done automatically.

- A calibration flap with an integrated gate prevents any seed from dropping into the hose.

The u-drill plus has been designed for precise fertiliser placement whilst sowing. It is able to apply fertiliser rates up to 400kg/ha (depending on speed and width). The pressurised hopper system of the 6.0m version ensures that these rates are maintained even under the most difficult conditions. Depending on the individual agronomic requirements, the fertiliser can be applied either directly in the seeding row or in between two rows.

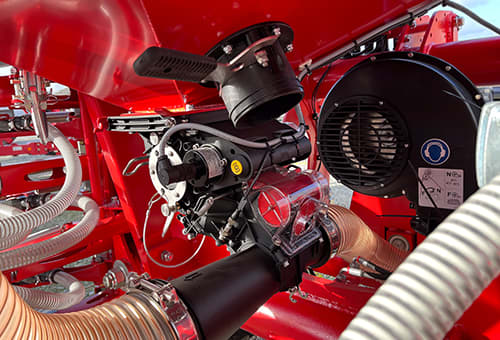

Fertiliser placement within the disc harrow section

The outlets within the second row of the disc harrow section apply the fertiliser exactly in between two sowing rows. All plants have exactly the same distance to the incorporated fertiliser placed. By adjusting the working depth of the disc harrow, the depth of the fertiliser placement is determined.

Fertiliser placement within the seeding row

The fertiliser application within the seeding row is done by the double-entry CD coulter. The fertiliser is placed together with the seeds. This is especially suitable for phosphoric fertiliser in order to support the initial germination and development of the plants in the most efficient way.

Sowing of two different crops

The special design of the double-entry CD coulter with two exits also allows the sowing of two different crops in just one working pass.

Presisjonslandbruk

Når du skal bestemme deg for hvilket utstyr du skal kjøpe, er det ikke alltid lett å finne den optimale løsningen i dagens brede markedstilbud. Teknologien utvikler seg raskt og traktorer og redskaper er mer og mer utstyrt med høyteknologisk elektronikk. Vi forstår denne kompleksiteten og er forpliktet til å gi deg enkle løsninger. Derfor er disse ISOBUS Universale Terminalene , IsoMatch Tellus PRO og IsoMatch Tellus GO + laget for enkel maskinstyring og effektiv drift.

Med sine avanserte maskinvare- og programvarefunksjoner, gir IsoMatch Tellus PRO den optimale presisjonsløsningen for et alt-i-ett-kontrollsystem inne i traktorhytten.

IsoMatch Tellus PRO er midtpunktet for tilkobling av alle ISOBUS-maskiner og en plattform for kjøring av presisjonsbruk. Den tilbyr alt en bonde trenger for å få maksimalt ut av sine maskiner og avlinger, samt kostnadsbesparelser i gjødsel, kjemikalier og frø ved hjelp av automatisk seksjonskontroll og variabel hastighetskontroll. Med den unike dobble skjermfunksjonaliteten gir vi bonden mulighet til å se og kontrollere to maskiner og prosesser samtidig.

Arbeid enkelt . Ha kontroll

IsoMatch Tellus GO + er spesielt utviklet for å kontrollere maskinen på en enkel måte. Bonden har full kontroll over maskinen akkurat slik han vil. Enkelt å sette opp maskinen med funksjonstastene via 7-tommers touch skjerm. Du har optimal kontroll under kjøring, bruk bare hardtastene og dreiebryteren. Det har aldri vært så enkelt å kontrollere redskapet.

Dette kan være deg ditt første skritt inn i Presisjons Landbruk

IsoMatch Tellus GO + gjør det enkelt å kontrollere hvilken som helst ISOBUS-maskin fra traktorhytten din. IsoMatch GEOCONTROL lar deg oppnå høyere avkastning, lavere kostnader og gjøre arbeidet ditt med mindre problemer. Denne lisensnøkkelen er delt i to deler, seksjonskontroll og variabel hastighetskontroll, som er tilgjengelig fra IsoMatch Shop. Nå kan du kjøpe den spesifikke funksjonaliteten du trenger.

Med visuell veiledning er du alltid på rett spor.

IsoMatch InLine er en LED-lampe som gir tydelig indikasjon om plassering.

Den er et utmerket hjelpemiddel for å komme så nær som mulig til ønsket A-B linjen. Rett plassert i synsvinkelen, kan du enkelt se avstanden fra A-B linjen og til hvilken retning du må styre for den ideelle posisjon. På displayet kan du også enkelt se hvilke redskapsseksjoner som er aktive. LED-lampen kan tones ned for nattkjøring.

SMART |

IsoMatch Global er et viktig tilbehør for IsoMatch GEOCONTROL.

IsoMatch Global er en GPS-antenne med DGPS-nøyaktighet, som gjør det mulig for bonden å navigere for stedsspesifikk seksjonskontroll, bruke applikasjon med variabel hastighet, manuell veiledning og feltregistrering

SMART

Tillater manuell veiledning, automatisk seksjonskontroll og variabel hastighet i kombinasjon med IsoMatch GEOCONTROL

EFFEKTIV

DGPS-nøyaktighet uten ekstra abonnementsgebyrer

ENKEL

Enkel å montere med monteringsbraketter inkludert.

Laget for smart, effektiv og enkel styring

IsoMatch GEOCONTROL er et avansert program innen IsoMatch Tellus PRO og IsoMatch Tellus GO som hjelper deg med å kontrollere alle ISOBUS-kompatible Kverneland redskaper som sprøyter, spredere og såmaskiner! Kombinert med en GPS-mottaker oppfyller de fremtidige behov med hensyn til enkelt, smart og effektiv styring!

IsoMatch MultiEye er et tilbehør for tilkobling av flere kameraer til IsoMatch Universal Terminaler.

Med IsoMatch MultiEye kan du ha flere kamera tilkoblet IsoMatch Tellus Universal Terminalen. Og du kan bytte mellom kameraene uten å ha en ekstra skjerm i traktoren..

Det gir deg full kontroll og oversikt over hele maskindriften dag og natt, på grunn av sin nattsyn med integrert LED . Dette øker sikkerheten når du rygger maskinen eller manøvrering rundt hindringer.

|

SMART Du kan koble til opptil fire IsoMatch Eye kameraer og enkelt veksle mellom kameraene med fjernkontrollen som er inkludert. EFFEKTIV Full kontroll og oversikt over hele maskindrift fra hver side du vil. LETT Se i mørket ved bruk av integrerte LED som øker sikkerheten når du rygger maskinen eller manøvrering rundt hindringer. |

IsoMatch Grip er utviklet for god førerkomfort og effektiv maskinstyring. Den ergonomiske formen og den totale friheten til å kontrollere totalt 44 redskapsfunksjoner fra en enhet er unik i markedet i dag. Du får uendelige muligheter til å betjene alle maskinfunksjonene etter ditt eget ønske. Og oppgaver lagres per maskin, noe som gjør det enda mer aktuelt for dine behov.

IsoMatch Eye inngår i serien med tilbehør og er et smart kamera tilpasset landbrukets krav.

IsoMatch Eye er spesielt utviklet for å passe til IsoMatch Tellus eller Tellus Pro terminalen, som har doble skjermer. Den gir deg godt overblikk over arbeidet, både på dagtid og i mørket takket være den integrerte LED-belysningen. Sikkerheten økes ved rygging, eller når du kjører framover eller svinger rundt hindringer.

SMART |

Tekniske spesifikasjoner

Tekniske spesifikasjoner

Last ned brosjyreWorking Width |

Row distance (cm) |

Weight (kg) with front packer + track eradicators |

|

u-drill plus rigid |

3.0m |

12.5 / 16.7 |

4,800 |

u-drill plus rigid |

4.0m |

12.5 / 16.7 |

5,600 |

u-drill plus folding |

4.0m |

12.5 / 16.7 |

5,600 |

u-drill plus folding |

6.0m |

12.5 / 16.7 |

8,400 |